RECYCLING ELECTRIC VEHICLE BATTERIES IS ESSENTIAL TO SUPPORT THE EV INDUSTRY

COLUMN BY JOSEPH CHUNG, CALL2RECYCLE

The latest automotive innovation age is here as manufacturing regions and OEMs explore new opportunities in the Electric Vehicle (EV) market. The prospects are exciting. A full, well-functioning EV market (including manufacturing plants, dealers, maintenance services, and end-of-life support) has the potential to dramatically reduce the auto industry’s impact on Canada’s environment, alleviate consumers’ pain at the pumps, and spur economic growth.

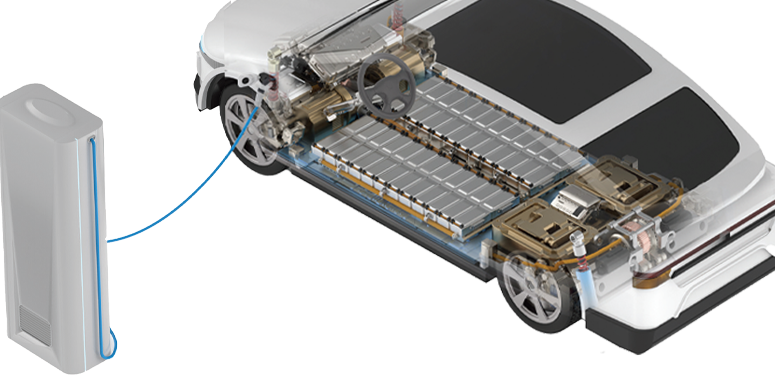

One of the biggest hurdles to achieving Canada’s 100 percent electric vehicle production goals by 2035 will be the production of EV batteries, which are manufactured using various precious metals and minerals, most notably lithium. The world’s mines can only produce about half of the critical minerals necessary to meet the industry’s goals. The rest is too costly to access. Both the cost-efficiency rationale and the sustainability effort to reduce the automotive industry’s environmental impact are major reasons for EV manufacturers to take action and set up a solid, Canada-wide infrastructure to support EV battery recovery.

This will allow the industry to effectively re-use, re-manufacture or recycle end-of-life batteries and make the best use of their components. Forty percent of the Automotive Recyclers of Canada’s (ARC) members say they are already processing end-of-life EVs. With growing numbers of EV batteries on the road, what will be done with them when they are no longer viable must be a key consideration. Do we want landfills brimming with EV batteries in a couple of decades? Certainly not.

Call2Recycle has been a battery recycling leader in Canada for more than two decades. We know that if Canada is to achieve its desired EV growth, a critical part of the market’s infrastructure must be a robust battery recycling framework. It’s a framework we understand deeply, having already built it in the household battery sector.

Over the last two decades, Call2Recycle has diverted more than 40 million kilograms of batteries from landfills to recycle their components into new batteries and other items. Through our network of battery collectors and processing partners, we operate a national program that is unparalleled in its efficiency and cost-effectiveness.

We have brought this same expertise to the EV space. Recognizing that we already had the infrastructure and capacity in place, Call2Recycle has been a key player in establishing and strengthening Canada’s e-mobility recycling capabilities since 2021. Working with recycling partners, we are exploring more opportunities to integrate and further expand our service. We are partnering directly with all of the OEMs and others in the automotive manufacturing and battery recycling industries to provide end-to-end EV battery services from coast to coast. With more than 130 e-Mobility collection sites nationally and growing, larger fire-retardant recycling boxes that accommodate longer vehicular batteries, and certifications for the safe transport of EV batteries, Call2Recycle is uniquely and expertly able to efficiently support the growing EV market and its players.

As we noted last year in a report co-authored with the Canadian Vehicle Manufacturers’ Association, EVs offer everyone on the supply chain tremendous opportunities for growth if done right. Provincial jurisdictions are increasingly making producers responsible for the end-of-life management of their battery products. There is little doubt that the EV market will be added to these regulations. Our report highlighted opportunities to improve the developing EV battery management ecosystem through greater coordination. That’s why we continue to collaborate with the industry to support the level of cross-border harmonization needed to strategically achieve sustainable EV growth and life cycle management. Recycling old EV batteries could reduce the need for new mining by 20 percent by 2040. The recycled materials are as pure and useful as freshly mined minerals, creating a genuinely circular economy.

Call2Recycle is already leading this effort. As more OEMs sign on to the Call2Recycle program for its convenience and national scope, we anticipate working with various collision repair providers to collect and recycle the EV batteries you receive. Together, we will ensure the country’s circular economy objectives for proper battery management are achieved in the simplest and most efficient way possible.