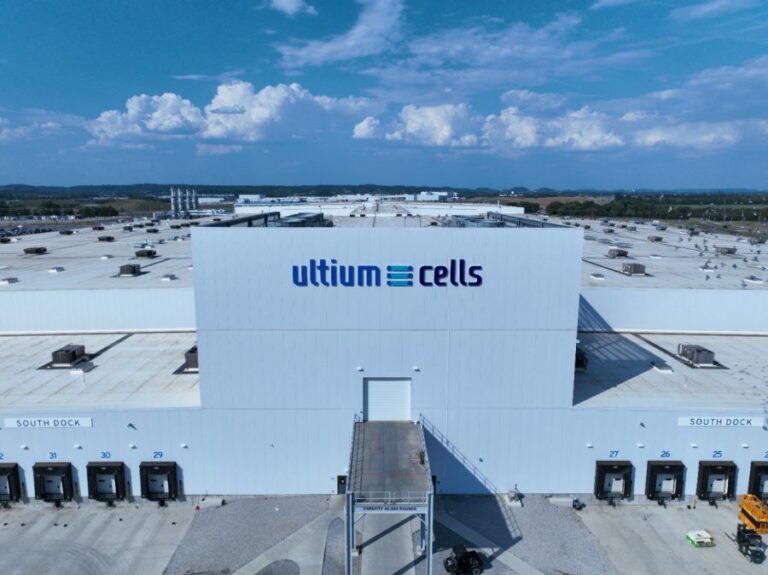

The facility was originally built to manufacture nickel-cobalt-manganese-aluminum batteries for GM’s electric vehicles. The company confirmed this month that it plans to retrofit the production line for LFP output later this year, with full-scale commercial production slated for late 2027.

“This upgrade at Spring Hill will enable us to scale production of lower-cost LFP cell technologies in the U.S., complementing our high-nickel and future lithium-manganese-rich solutions and further diversifying our growing EV portfolio,” said Kurt Kelty, vice-president of batteries, propulsion and sustainability at GM.

The move aligns with GM’s broader electrification strategy, which includes plans to launch a range of electric vehicles using different battery chemistries to serve a wider segment of the market. While NCMA cells offer higher energy density and longer range—over 300 miles per charge according to GM—the LFP chemistry is known for its cost-effectiveness and long cycle life, making it well suited to more affordable EV models.

Ultium Cells’ Warren, Ohio plant will continue to produce NCMA batteries, while the Spring Hill site adds flexibility to the company’s battery supply strategy. GM and LG say their Ultium platform is designed to accommodate multiple battery types and form factors, allowing the automaker to adjust chemistry and performance targets as market needs evolve.

Wonjoon Suh, president and chief innovation officer of LG Energy Solution, said the upgrade will bring additional agility to the North American EV supply chain.

[NP] “We will bring our extensive experience and expertise in U.S. manufacturing to the joint venture facility, further accelerating our efforts to deliver new chemistries and form factors that effectively capture the unmet needs in the EV market,” he said.

The Spring Hill facility opened in 2023 as a $2.3-billion investment between GM and LG, part of a broader push to secure domestic EV battery production and reduce reliance on foreign suppliers. The introduction of LFP capacity reflects growing demand for more affordable EVs as automakers attempt to meet both consumer expectations and regulatory targets.

With the upgrade, GM positions itself to compete more directly in the entry-level EV market, while retaining its higher-range models powered by NCMA and future lithium-manganese-rich batteries.