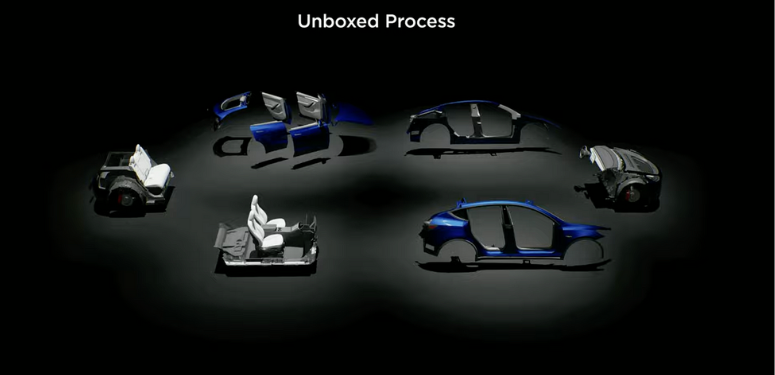

Toronto, Ontario — Tesla reportedly plans to implement a new “unboxed” manufacturing method in order to create its more affordable, $25,000 dollar electric vehicle (EV).

Unlike the traditional automotive assembly line in which a car—or rectangular ‘box’—is put together in stages at set stations, the “unboxed” method would have multiple different sections of a vehicle assembled at the same time in a dedicated areas of the factory and then put together in a series of large sub-assemblies.

The automaker claims that this method could potentially halve production costs while also requiring around 40 percent less space than a traditional car factory with the same output.

Tesla CEO, Elon Musk has reportedly alluded to this new manufacturing approach on several occasions over social media, although has not provided any substantial details. However, he’s said that the way Tesla plans to build its $25,000 dollar EV is “revolutionary.”

The affordable Tesla is supposed to enter production by the end of 2024 or the in the beginning of 2025 and Musk has confirmed that the project is “very far along,” but again, has not added any further details.