Toronto, Ontario – In this week’s electric and autonomous vehicle report, Honda made a deal with GM to use Ultium battery technology on upcoming EVs, a Toyota subsidiary has found a cheaper option for AV data collection and the “Centre of Excellence” technology lab is turning out to be a hub of innovation.

EV Treaty

In an interesting development for OEM relations, Honda announced that it has partnered up with General Motors to utilize the Detroit automaker’s Ultium battery technology in upcoming Honda EVs.

With initial rollout projected to begin in 2027, Honda expects this partnership to help standardize EV production equipment and practices, in turn driving down the overall cost of electrification.

“Honda is committed to reaching our goal of carbon neutrality on a global basis by 2050, which requires driving down the cost of electric vehicles to make EV ownership possible for the greatest number of customers,” said Honda president and CEO Toshihiro Mibe.

“Honda and GM will build on our successful technology collaboration to help achieve a dramatic expansion in the sales of electric vehicles.”

Snapping up the Savings

Toyota subsidiary and autonomous systems developer, Woven Planet, told Reuters it is following Tesla’s lead and scaling back the use of LiDAR in favour of cheaper, but equally effective cameras for the purposes of vehicle data collection.

Collecting wide samples of vehicle data can be expensive when using LiDAR technology, however, Woven Planet pointed out that lower-cost cameras can be used to do the job on a larger fleet of vehicles.

“We need a lot of data. And it’s not sufficient to just have a small amount of data that can be collected from a small fleet of very expensive autonomous vehicles,” Woven Planet’s v-p of engineering, Michael Benisch.

Woven Planet’s cameras are 90 percent cheaper than the sensors they were using previously.

Excellent Innovations

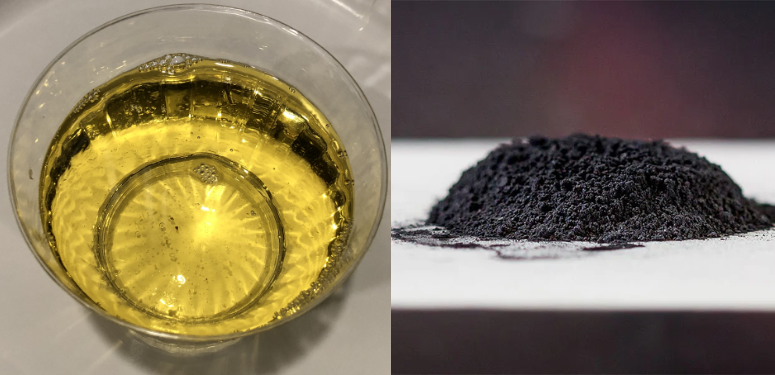

The engineers at the “Centre of Excellence,” a technology lab jointly run by Electrify Canada and Electrify America, have been hard at work over the past months sorting out solutions to the most common problems affecting EVs today.

The team based in Reston, VA had been working to address the issue of heating and fire risks associated with the EV charging process, which resulted in the development of liquid-cooled charging cables that come without a significant increase in thickness for charging power at and above 150kW and up to 500 amps.

The centre was also instrumental in developing Plug&Charge Technology, a payment method that allows customers with capable vehicles and a payment method set up with their vehicle manufacturer to plug in and pay without opening an app or wallet.

Since beginning operations in 2017, engineers and technicians at the Centre of Excellence have conducted more than 8,000 hours of interoperability tests on production and prototype EVs from nearly all vehicle manufacturers.